Operational Expertise, Embedded in Software

Our approach is grounded in field reality: workflows, constraints, data variability, and the need for fast, dependable answers during operations.

Wellcoms helps operators and service companies transform operational drilling data into reliable indicators and actionable intelligence. With more than 15 years of experience supporting real-world rig operations, we embed proven engineering logic into our solutions—while preparing the next generation of predictive capabilities.

Our approach is grounded in field reality: workflows, constraints, data variability, and the need for fast, dependable answers during operations.

Deep partnerships with operators and service providers inform every aspect of our platform design and algorithm development.

We account for data gaps, mixed sources, bandwidth limits, and the realities of offshore and onshore rig environments.

Our algorithms reflect best practices from drilling engineering, ensuring decisions are grounded in domain expertise.

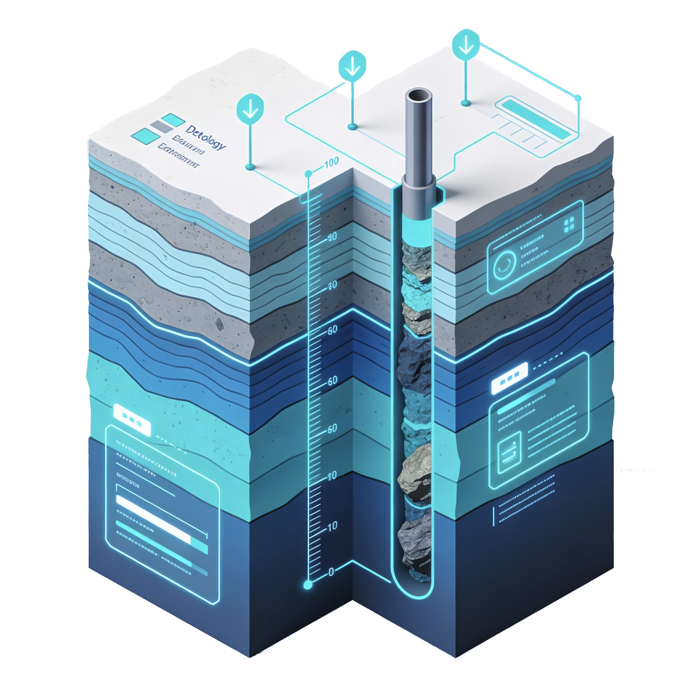

We design and implement algorithms that translate raw streams into meaningful operational states and KPIs—so teams can monitor, compare and react consistently.

Tailored to operational usage patterns, our algorithms derive reliable operational states from heterogeneous data sources.

Unified operational status derived from mixed data sources, eliminating confusion and enabling faster decision-making.

Real-time KPIs designed for operational dashboards and reporting, ready for benchmarking and performance analysis.

Good decisions require trusted data. Wellcoms embeds data quality controls directly into data pipelines and applications to detect anomalies, inconsistencies and missing critical signals early.

Automated consistency checks and validation rules integrated throughout the data pipeline.

Early identification of missing signals, out-of-range values, and incoherent transitions in operational data.

Full traceability of data quality issues to support troubleshooting and continuous process improvement.

We support the foundation needed to improve performance and reduce uncertainty—by structuring data, indicators and monitoring logic around operational objectives.

Context-aware indicators that help teams understand drilling workflow implications and operational constraints.

Performance metrics ready for comparison across wells, rigs, and time periods for continuous optimization.

Designed to integrate seamlessly with WITSML™ and ETP standards for industry-wide compatibility.

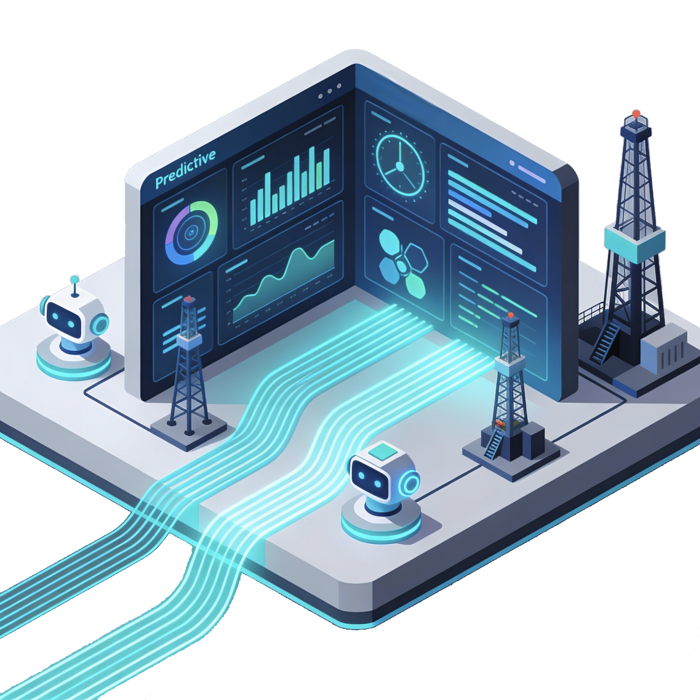

We are preparing new capabilities to support drilling performance optimization through predictive models and automated detection mechanisms.

Machine learning models to forecast drilling performance and identify optimization opportunities ahead of time.

AI-powered systems to detect operational anomalies automatically, reducing manual monitoring burden.

Intelligent recommendations to accelerate decision-making and reduce operational uncertainty on the rig.

More reliable, consistent operational status across all data sources for faster, more confident decision-making.

Identify data quality problems and operational anomalies before they impact drilling performance or safety.

A robust, extensible platform ready to grow with your operations and accommodate new data sources.

Built with the architecture needed for next-generation predictive and AI-driven drilling intelligence.

Discover how Drilling Intelligence can optimize your operational performance and accelerate decision-making on the rig.